Let me tell ya, this whole “supply chain car” thing, it’s like when ya tryin’ to make a big ol’ meal for the whole village, and if even one part’s missin’ or a bit late, the whole thing gets all messed up! Ya see, the car-making process, it ain’t simple as some think. From the tires, seats, engines, right down to the little parts inside – every little bit gotta come together just right. It’s like a line of folks passin’ buckets o’ water, one slip and water’s spilled, and ya gotta start over!

What Exactly Is a Car Supply Chain?

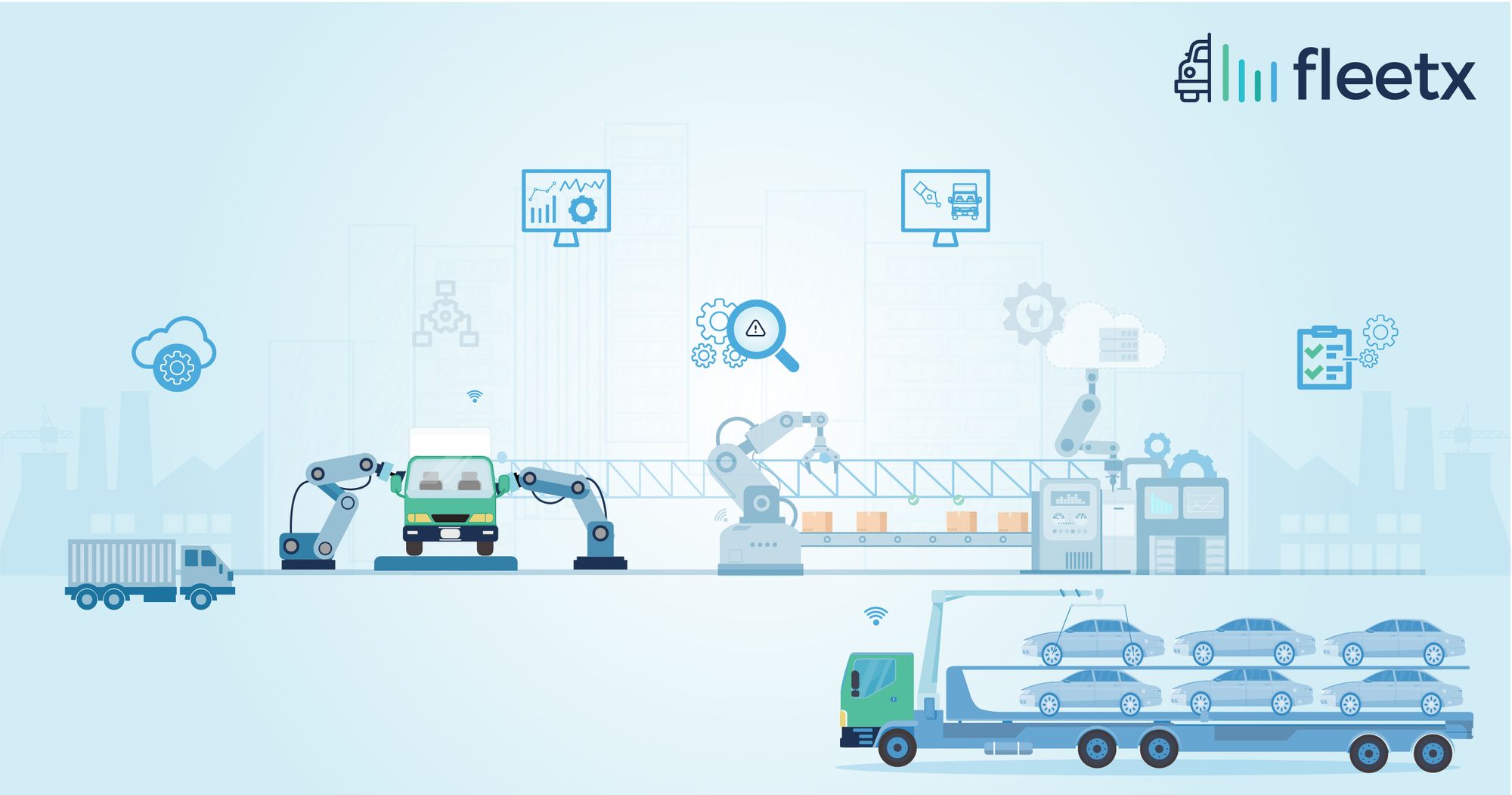

Now, first off, when we talk ‘bout this “supply chain” stuff, we mean the whole journey from takin’ raw materials to buildin’ up every bit of a car, till it’s ready to drive. From the folks who dig up the metals for parts to the factories makin’ each piece, there’s a lot that goes on. It all gotta run smooth like a good ol’ river. If somethin’ breaks down in between, the car won’t be ready, or maybe it’ll cost more, or be hard to find in the store!

Imagine big companies like Toyota or Tesla – now, they got their own supply chain dance goin’ on. They need to make sure the parts are comin’ from everywhere, on time, no delays. And just like us worryin’ if the hens gon’ lay eggs on time, they got their worries too! If somethin’ goes wrong, all them cars we see on the road might just be fewer and cost a lot more.

Why the Supply Chain Gets Stuck Sometimes

Things don’t always go right, ya know. Weather could get bad, ships stuck at ports, or even problems like folks not wantin’ to work due to some reason or other. These things hit the car supply chain hard. And cars got hundreds of little parts, mind ya. If one tiny part don’t show up, say a chip or wire, the whole car waitin’!

Now, lemme give ya an example. Imagine Tesla waitin’ on them fancy electric batteries. If the batteries don’t come in time, them electric cars ain’t goin’ nowhere. So, if the supply chain got issues, they have to hold back, just like we’d hold back our plowin’ if rain don’t come on time.

- Delays with Materials – Metals, plastics, and them chips – if somethin’ slows down at the mine or factory, then whole production slows down.

- Shipping Problems – Now ya got these big boats carryin’ stuff across the seas, but if one boat gets stuck, like in some big canal, well, that’s trouble for everybody.

- Factory Shutdowns – Sometimes a factory might shut down ‘cause o’ sickness or weather, and that means parts don’t get made.

How Car Companies Try to Fix These Chain Troubles

Now, big car folks like Ford, GM, and Honda, they don’t just sit back when supply chain issues hit. They be workin’ hard, figurin’ out ways to make sure they can still make them cars. Here’s some things they try:

- Keepin’ Extra Parts Handy – Sometimes, they keep a buncha extra parts so if somethin’ goes wrong, they still got enough to keep makin’ cars for a bit.

- Choosin’ Different Suppliers – If one supplier got trouble, they look for others to fill in so the work don’t stop.

- Makin’ Parts In-House – Companies like Tesla sometimes make important parts in their own factories, so they don’t gotta wait on nobody.

How This All Matters to Folks Wantin’ to Buy a Car

Now, what does this supply chain stuff mean for folks lookin’ to buy a car? Well, when the chain gets all tangled up, it means car prices go up. If parts are harder to get, or costs more to ship, then them companies gonna charge more for the cars. So, ya see, supply chain problems don’t just stay with the factory folks, it comes all the way down to the buyer too.

For example, if there’s a chip shortage, like they had recently, that means cars needin’ chips for fancy features might get delayed, or cost more. And folks like me just want a car to go from here to there, so we ain’t too happy when we gotta wait longer or pay more ‘cause a little chip was late!

What’s Gonna Happen with the Supply Chain in Future?

Now, folks talkin’ about makin’ things smoother in the future. They lookin’ to build factories closer to home so they don’t gotta rely on stuff comin’ from far. Like here in the ol’ village, it’s better to grow our own veggies than waitin’ for ‘em from other places. Car companies thinkin’ the same way. They call this “localizing,” meanin’ makin’ parts closer so they ain’t stuck waitin’ on long trips.

So in the end, the supply chain for cars is mighty important. It’s like a big ol’ relay race, where every runner gotta pass the stick on time, or the race gets slowed down. And ya know, even big ol’ car companies got struggles just like us folks in the village tryin’ to keep things movin’. When they get it right, we all get our cars on time; when they don’t, well, we might be walkin’ a bit longer!

Tags:[Supply Chain, Car Production, Automotive Industry, Delays, Costs]